Serrated Blade

The worst function of a knife meant for regular use is a serrated blade. Serrated blades are slow to sharpen, never make a clean cut, and can be hard to keep clean. Even a knife with only a little serration is poor for a general-use knife.

The purpose of serration is three-point. First off, you have more cutting surface packed into each inch of blade. Because the blade had such depth of texture, you get a lot more cutting surface and that’s sort of a good thing, right? The second point of serration is that you usually retain some sharpness even after using it a lot. As the edge wears down, the highest points of the serration get quite blunt but the lowest remain fairly sharp because that lower part of the blade has done a lot less work.

The issue with this to me is that the serrated edge design is basically meant to function as a lesser sharp knife but for longer. I would rather prefer a nice, sharp clean-profile blade that I can use, and then hone to a nice new sharp edge.

The third point of serration is that it can be used for a minimal sawing action. Many so-called “survival” knives have serration so you can sort of almost saw small sticks and twigs. In all honesty, a straight, sharp blade is better.

Serrated blades are fairly tricky to sharpen. Most of them have very small, tight serrations these days which requires a very skinny sharpening stick to be able to hone the blade. Those skinny sticks don’t last long, even with a diamond stick. You also have to go slow when sharpening them. I bought a Dewalt pocket knife when I was in a bind. It’s half-serrated. I filed the serration off.

If you’re looking for a nice but not too-expensive knife, Check out Buck Knives with this ad link below.

Recurve Blade

The recurve blade is a design that looks nice and sleek, and it can aid in the cutting function of some cutting tasks. The problem is that they require specialized sharpening equipment. and are usually harder to get a good edge on because of it. A recurve blade simply means that it has an upswept curve somewhere in the middle of the blade. It’s even more of an issue on smaller knives.

The problem is that with the upswept or concave curve in the blade, you can’t sharpen it with a normal sharpening stone. you will end up tearing up both the knife and the stone, and not getting much progress in honing your knife. It’s not just that it’s curved, all good knives have a good corve somewhere in the blade. The problem is that if I lay a recurve knife on a normal, flat stone, The blade will only contact along the edges of the stone and that will just tear down your stone.

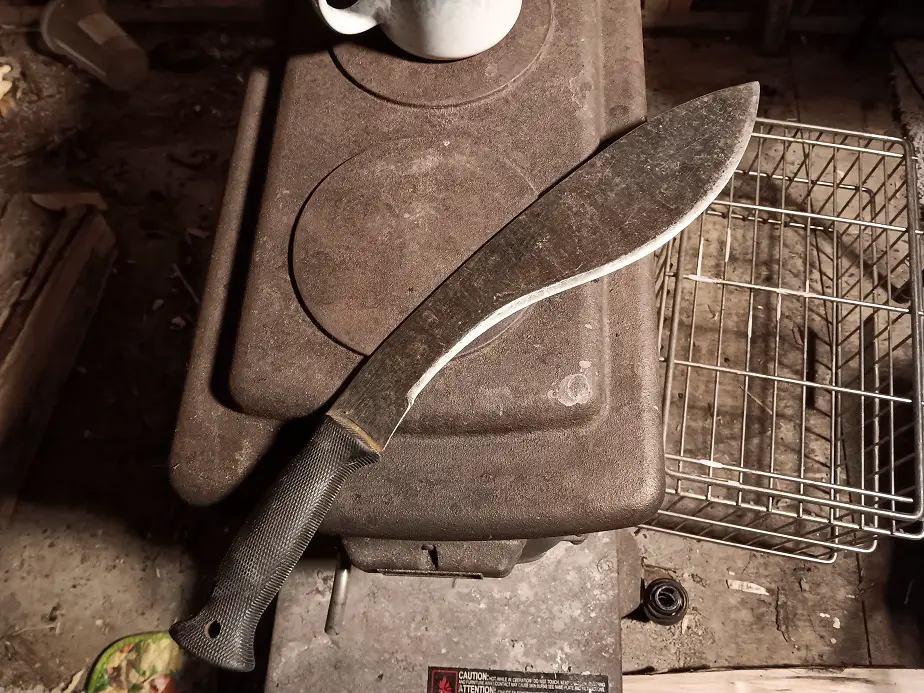

I actually do have a recurve blade. It’s a semi-Kukri design machete that I use quite a lot. It split up some kindling for my woodstove this morning, I use it to cut grass for my rabbits and pigs, and to trim back the briars along my property line. But, I cannot sharpen it on my whetstone. I can only sharpen it with a stick or rod. The issue with that is that most sharpening sticks and honing rods either don’t do a very good job or they are a little tricky to use compared to a stone.

I’m okay with my recurve machete when I need it because the design helps it cut grass, but I’d never want one for my general-use knife because I can’t really sharpen it without a hining rod of some sort. There are some wonderful recurve knives out there, like the Puma Buffalo Hunter. I gave that knife to the men who stood at my wedding. Just remember, it requires specialized sharpening equipment.

Tanto Point

The Tanto Point got popular about 10 years ago for no other reason than it was different and looked cool. It was marketed as “tactical”. While it serves a small purpose, the Tanton Point design is quite annoying for a lot of knife work. It’s poor for skinning game, it’s not easy to sharpen evenly, and it’s not much of a piercing point.

The purpose of a Tanto Point is just to have a cutting surface on the front instead of much of a point. It was supposedly for a militaristic purpose. It’s supposed to be halfway between a curved tip and a pointed tip. Unfortunately, it’s not so great in the field. My Dewalt pocket knife, which is still in my back right pocket, was a tanto. It’s not anymore. I filed it rounder.

Soft Steel

Soft steel is one of the banes of a cheap knife. As a youngster, I had two cheap blades. They were stamped with ‘Pakistan’ on the side. They had cool handles and looked impressive to a boy. But golly they were soft steel. I could get them shaving sharp, but it never lasted very long at all. The smaller one would go dull halfway through dressing out a small deer.

I remember the blade on my large Pakistani bowie knife getting all bent up from splitting a deer pelvis and trying to chop small pine branches. A good steel will have a hardness of around 58 on the Rockwell hardness scale. My old Pakistani knives were probably about RC30 or RC35.

Buck Knives, the company I recommend, uses steel with an RC od between 58 and 60, depending on the blade structure. All I’ll buy anymore is a Buck knife. Click on the Ad link below to check them out.

I have found that a lot of the common knives in foreign countries, particularly the more second-world and third-world nations, are soft steel. This is probably for two reasons, First, because it’s a cheaper steel to source. You could get soft steel from the door of an old truck. Second, many times these folks lack good sharpening equipment and prefer a softer steel that can be sharpened on many of the common rocks and stones found in the ground.

Back when sandstone wheels were common for sharpening knives, softer steel was popular for knives in the US. I have to say, I’d still rather have a harder knife. I can find a stone of river granite or common chert and works just fine on a better-quality blade if I have to.

Hard Streel

Hard steel (RC68 or higher)is common in cheap knives and is used in some high-end knives. It’s incredibly tough to sharpen and can destroy a common sharpening stone or honing stick. My wife has a small kitchen knife that came free with the purchase of something. I almost can’t sharpen it. After resorting to a bench grinder to give it a new edge, I still couldn’t get it all that sharp after 20 minutes on my stone.

In hunting knives, it’s usually the higher-end ones that are too hard. It’s a selling point of “long-lasting sharpness” and “best-lasting edge”. Anything with a hardness higher than about RC 60 is best used as a presentation knife. My dad has a fancy Ducks Unlimited knife that came with a wooden box. That blade is almost unsharpenable. What’s the point if you almost can’t sharpen it?

Folding Blades

Folding blades make poor hunting knives because they are hard to clean, screws come loose, and locks wear out. If you skin or field dress animals with a folding blade, they get full of blood and grime that’s hard to get out. Most folding knives are weak and prone to breakage, bending, and general failure. They are not to be relied upon if you had to trust your life to a knife.

I nearly lost my finger once when the lock on a folding knife failed and it closed right on my knuckle. A nice deep cut right through the knuckle joint isn’t fun. I’ve used a lot of folding knives from the woods to the water. It’s handy to carry it in your pocket, but folding knives are by nature a weak design and most of them just don’t do well with much use.

That brings me to the three knives I have now. I currently have a Dewalt pocket knife in my pants pocket, It’s a junk knife. It was quite cheap, and almost worth it. I really need to stop using it because the blade is getting loose for the third time.

In my backpack, used for any outdoor excursion or unplanned emergency, I have two blades. The first is a Morakniv Companion. It’s a $25 knife with good steel and a cheap-looking yet somehow sturdy handle. I use it to shave tinder, whittle sticks, and dress out game animals. It works, but it’s not the most heavy-duty knife. Its main issue is that it’s very lightweight and has absolutely no heft to it. That means it’s not as good for campwork.

My other knife is a Buck 119. It’s my favorite. I love Buck knives. Check out the Buck 119 in this link

They are the only one left of the older hunting knife companies that are still producing MADE IN THE USA. The Buck 119 is longer, bigger, and heftier than the lightweight Morakniv. It’s just hefty enough to be useful as a camp knife, and it’s a great all-around outdoors knife. If I were heading off into the north woods, I would be okay with the Buck 119.

I do highly recomend Buck Knives for a dependable blade in the woods.